Product

KT 1050[1+18+1]

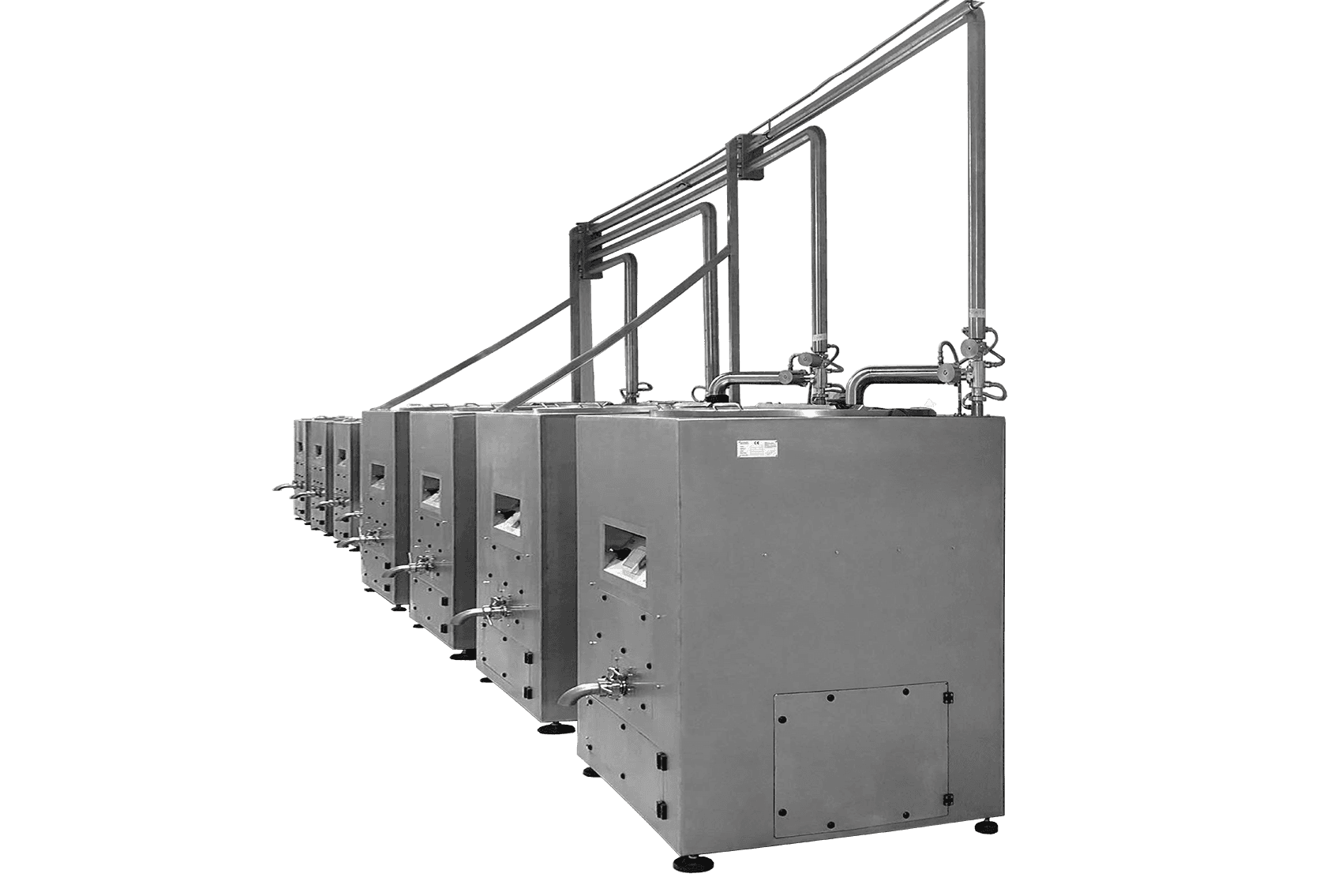

Cooling tunnel - economic or industrial model

The cooling tunnel with convection and radiation cooling tailored to your application and budget. Whether you want to cool chocolate, cake, biscuits or other products, the KT 1050 is always a smart move. Depending on your needs, available space and your budget, the KT 1050 is available in two models.

Do you work with smaller volumes and a smaller budget? In this case the basic model is the best choice. This model has a non-insulated chassis and a return belt that is not cooled.

Do you work with bigger volumes and a bigger budget? In this case the industrial model is what you need. It has a double-jacketed chassis and cooled return belt.

Both models are equipped with convection and radiation cooling. The water cooled bottom plate is optional.

The cooling tunnel KT 1050

Features:

- an infeed belt with a nose that can be adjusted in height and length

- an infeed belt the length of your choice to decorate and/or dose on the cooling belt

- food-grade conveyor belt, where the return belt returns to the cooled space (in the industrial model)

- a belt scraper

- a PID temperature regulator

- hinged covers

- an adjustable infeed belt for decorating

- detaching belt at the end of the tunnel

- automatic control

- pneumatic or mechanical belt tensioning

- radiation and/or convection cooling

Options:

- decorator (granulate and/or chocolate)

- extra cooling length per 1 to 2 metres

- water cooled bottom plate

- vibrating table under the infeed belt of the cooling tunnel

- cooling unit outside the production space

- mobile vibrating system for blisters or polycarbonate moulds

-open%20-%20Photo-2018-05-25-17-10-32%20B_.png&w=1500&q=60)

-open%20-%20Photo-2018-05-25-17-10-32%20B_.png&w=1920&q=60)