The crucial role of BETEC cooling tunnels in the chocolate industry: Rapid and precise cooling for a perfect result

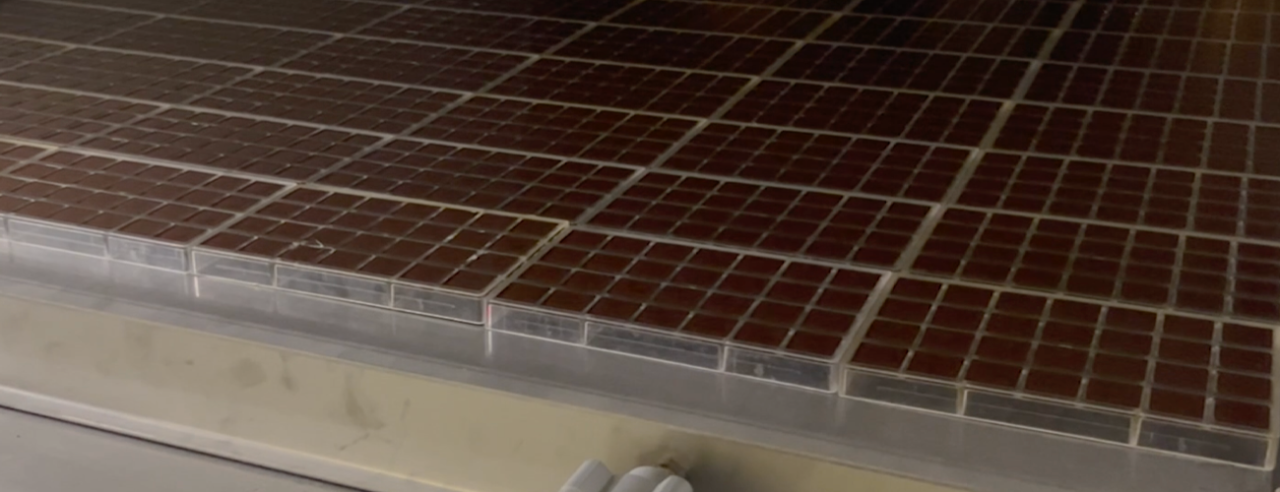

Cooling products with BETEC cooling tunnels. The crucial final step in the production process of chocolate products is the cooling of the product. Often underestimated, the correct cooling method is of paramount importance, especially when using real chocolate. Even with the highest quality and perfectly tempered chocolate, the end result can be disappointing if the cooling process is not done correctly.

.png)

The essence of perfection lies in the indispensable role of proper cooling in chocolate production.

A wide range of available cooling tunnels for various application

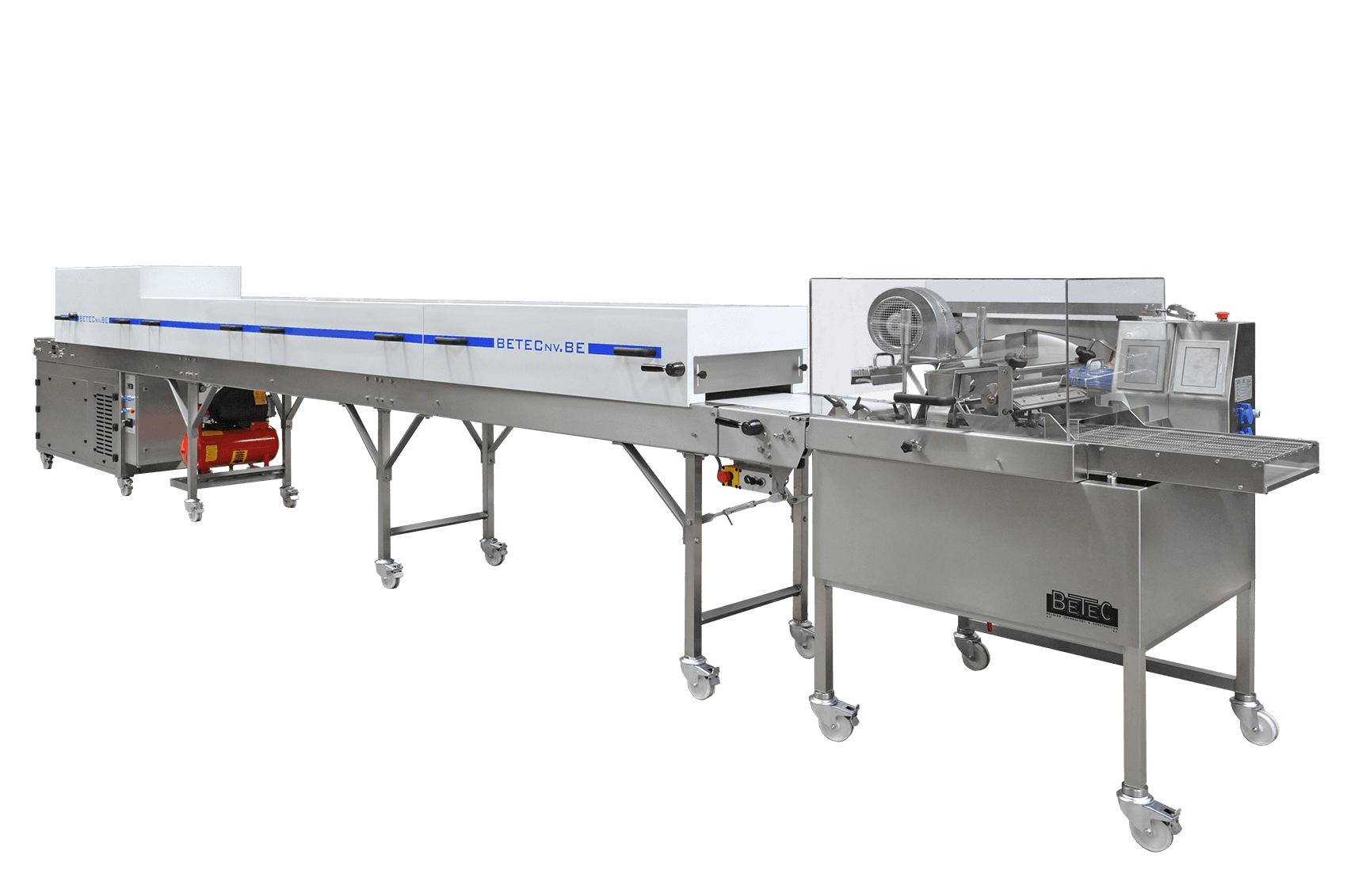

Betec designs, manufactures, and installs various types of cooling tunnels suitable for a wide range of applications in the food industry. Whether you want the cooling unit integrated into the cooling tunnel or placed outside the production space, the choice is yours. We offer both horizontal and vertical configurations, including :

Cooling tunnels with PU conveyor belts:

Commonly used in the chocolate industry, are equipped with a PU conveyor belt. These tunnels are typically placed behind an enrober, glazer, or coating machine to cool glazed, coated, or chocolate-covered products. Betec cooling tunnels are generally equipped with both convection and radiation cooling. Radiation cooling, also known as indirect cooling, ensures that the cold air does not come into direct contact with the covered or coated product, which is crucial when working with real chocolate. The switch from radiation to convection cooling is simple; with a manually operated valve, you can switch from convection to radiation cooling. As an option, there is the possibility to use a water-cooled bottom plate, significantly increasing the cooling capacity.

Horizontal mould cooling tunnel/ Cooling tunnel with modular belt

Discover the effectiveness of our automatic horizontal mold cooling tunnel. Manually placing polycarbonate molds on racks and refrigerating them is time-consuming. Therefore, we introduce our automated solution. The length of the tunnel is tailored to your production capacity, and for locations with limited length space, our tunnel offers flexibility by widening it and equipping it with an automatic return system. Effortlessly operate the system via the touchscreen color display, complying with the applicable CE standards. Personalize it with optional features such as an automatic input and output system, a mold twist-release system, and an automatic demolding system. Enter a new dimension of efficiency and precision in your production process with our horizontal mold cooling tunnel.

Vertical mould cooling tunnel, paternoster cooling tunnel in a refrigerated cell:

Used for cooling hand-poured or automatically molded chocolate forms. The filled molds, whether with tempered but still liquid chocolate or not, then enter the vertical molded cooling tunnel and emerge perfectly cooled and crystallized at the end, ready for immediate demolding.

Horizontal cooling tunnels, cooling spirals, and spiral freezing towers with modular conveyor belts:

Both configurations are highly suitable for cooling molded chocolate moulds, prepared meals, and more. In both configurations, convection cooling is typically used, where cold air is blown directly onto or under the product to be cooled, ensuring efficient cooling capacity. Spiral cooling towers are supplied with or without a refrigerated or frozen cell. If supplied without a refrigerated or frozen cell, the product is usually cooled by ambient air. When a spiral cooling tower is placed in a refrigerated or frozen cell, temperatures of up to -30 degrees Celsius can be achieved. Spiral belts are commonly used in industrial bakeries for cooling waffles, pastries, and bread, and in the ice cream industry for cooling freshly made ice cream.

.png)

Why choose between a horizontal cooling tunnel or a spiral tower with a modular belt:

The significant difference between a horizontal cooling tunnel and a spiral tower with a modular belt lies in the required footprint. A spiral cooling tower with a modular belt makes more efficient use of the available space compared to a horizontal cooling tunnel equipped with a modular conveyor belt. In other words, the spiral cooling tower can accommodate a greater length of conveyor belt on a smaller footprint than the horizontal cooling tunnel with a similar modular conveyor belt. This can have advantages in maximizing production capacity and optimizing available space in a production environment.

Curious about all the possibilities?

Browse through our online catalog or contact us for a non-binding quote.

Through the links on the side, you can view our applicable products:

- Spiral conveyor belts

- Spiral cooling tower

- Spiral freezing tower

- Vertical cooling tower, paternoster cooling system

- Cooling tunnels with PU conveyor belts

- Cooling tunnels with modular conveyor belt, horizontal cooling tunnel

![BETEC KT 240[0.5+5.5+0.8]](/_next/image?url=https%3A%2F%2Fbetecnv.adminbeheer.be%2Fadmin%2Ffiles%2FFoto-11_KT-240(0%2C5%2B5%2B0%2C7)-M1-M8.png&w=1920&q=60)

%20-%20DSC_8946%20C%20.png&w=1920&q=60)

%20-%20DSC_7772%20B%20(1).png&w=1920&q=60)

![BETEC KT 450[1.8+6+1]](/_next/image?url=https%3A%2F%2Fbetecnv.adminbeheer.be%2Fadmin%2Ffiles%2FFoto%2048_KT%20400%20-%20PHOTO-2019-10-21-19-38-17%20C%20.png&w=1920&q=60)

.png&w=1920&q=60)

.png&w=1920&q=60)

![BETEC KT 600[1,5+12+1,5]](/_next/image?url=https%3A%2F%2Fbetecnv.adminbeheer.be%2Fadmin%2Ffiles%2FFoto%2071_KT%20600(1%2C5%2B12%2B1%2C5)-close%20-%20DSC_4273%20G%20.png&w=1920&q=60)

![BETEC KT 1050[1+18+1]](/_next/image?url=https%3A%2F%2Fbetecnv.adminbeheer.be%2Fadmin%2Ffiles%2FFoto%2072_KT%201050(1%2B18%2B1)-open%20-%20Photo-2018-05-25-17-10-32%20B_.png&w=1920&q=60)