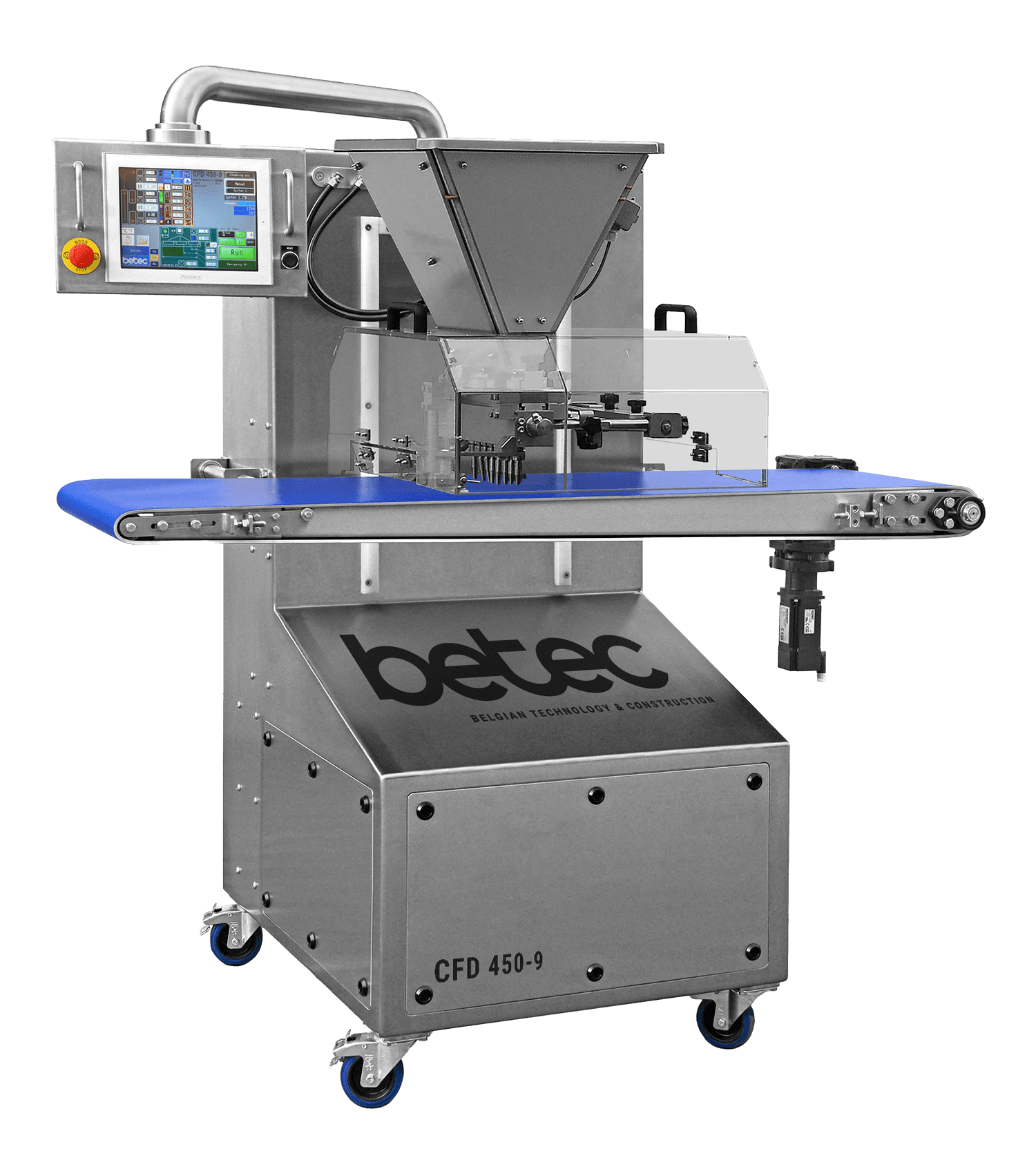

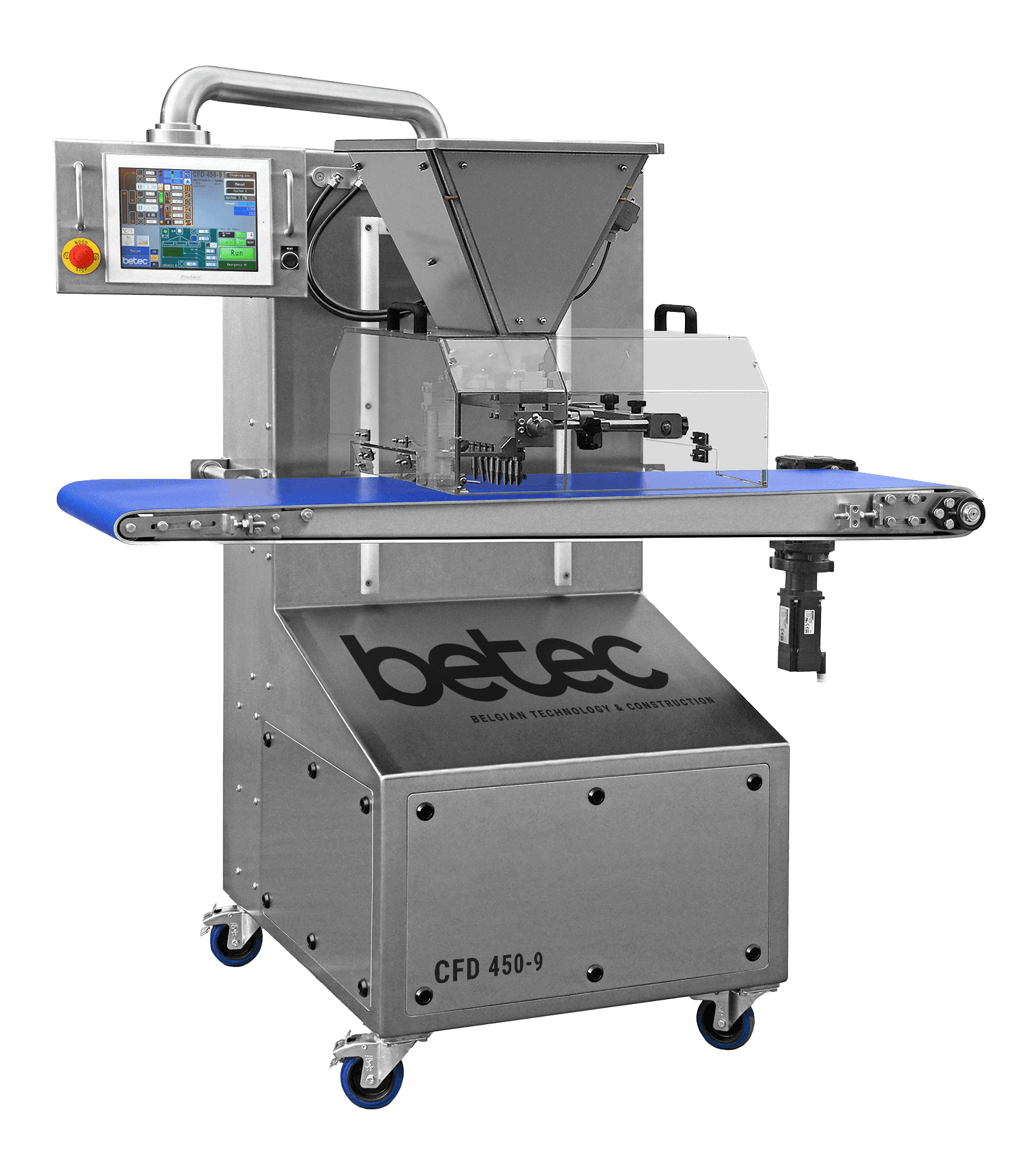

Product

CFD 450-9

Industrial Servo-Controlled Volumetric Depositor

The CFD 450-9 is an industrial servo-controlled volumetric depositor, designed with a strong focus on efficiency and precision. Each of the nine pistons can be individually switched on or off, allowing for maximum control and flexibility in dosing. Additionally, the machine comes with different interchangeable dosing plates and nozzle bars, available with 9, 8, 7, or 6 outlets, depending on the specific needs of your production process.

The water-heated dosing head allows you to set the temperature precisely, making it perfect for temperature-sensitive products. The fully removable dosing head, including plungers and hopper, enables quick and easy cleaning. Both the dosing quantity and dosing speed can be easily adjusted, and the infinitely adjustable suction-back feature provides additional control.

The CFD 450-9 is designed to handle interior fillings or creams containing ingredients or particles with a diameter of up to 5 mm, making it suitable for a wide range of applications. The electronic height control of the dosing head allows for precise adjustment of both upward and downward movements. Additionally, the dosing belt can be quickly and easily removed, allowing the machine to be placed above the input section of a moulding line or cooling tunnel, ensuring maximum flexibility.

The machine features a colour touchscreen for intuitive control of all settings, with the ability to store up to 100 different recipes. The removable hopper, with a capacity of approximately 20 to 30 liters, ensures efficient and easy throughput of raw materials.

In addition to the servo-driven version, a pneumatic variant is also available. While this version offers slightly less speed and precision, it is a more cost-effective option. When making the right choice, it is important to consider the production speed you want to achieve and how much variation in dosing is acceptable for your process.

Advantages of the CFD 450-9 Servo-Driven Volumetric Dosing Machine:

- High Precision Dosing, the servo-driven technology ensures accurate dosing of fillings and creams, even with inclusions or particles up to 5 mm in diameter.

- Individual Piston Control, each of the nine pistons can be independently switched on or off, offering maximum flexibility in the dosing process.

- Interchangeable Dosing Plates, the machine comes with interchangeable dosing plates, providing options for 6, 7, 8, or 9 outlets to adapt to various production needs.

- Electronic Height Control, the dosing head features electronic height control for precise adjustment of both upward and downward movements, ensuring optimal product handling.

- Easy Cleaning, the fully removable dosing head, including plungers and hopper, allows for quick and efficient cleaning, reducing downtime.

- Temperature Control, the water-heated dosing head ensures precise temperature regulation, making it ideal for temperature-sensitive products.

- Adjustable Dosing Settings, both the dosing quantity and speed can be easily adjusted, providing versatility for a variety of products and production rates.

- Suction-back Feature, the infinitely adjustable suction-back mechanism offers enhanced control to prevent drips and ensure clean dosing.

- Flexible Integration, the dosing belt can be quickly detached, allowing the machine to be easily positioned over a molding line or cooling tunnel for seamless integration into existing production lines.

- User-Friendly Interface, the color touchscreen offers intuitive control, with the ability to store up to 100 different recipes, simplifying the production process.

- Efficient Hopper Capacity, The removable hopper with a capacity of 20-30 liters ensures efficient raw material throughput for continuous operation.

Optional enhancements:

- Agitator in the hopper for an even mix

- Mould cooling tunnel and tempering machine for added flexibility

- Infeed and outfeed conveyors, mold stackers, and vibrating conveyors for an integrated production solution.

With the CFD 450-9, you’re not only investing in a machine that improves speed and accuracy, but also significantly boosts production volumes and profitability. Additionally, its wheeled frame makes it easy to move when not in use, offering even more convenience and flexibility.

The CFD 450-9 is the perfect choice for any professional chocolatier or baker seeking an efficient, high-quality dosing and filling machine.

Don’t leave anything to chance—boost your production speed and precision.

For more information or to place an order, contact us at info@betecnv.be.