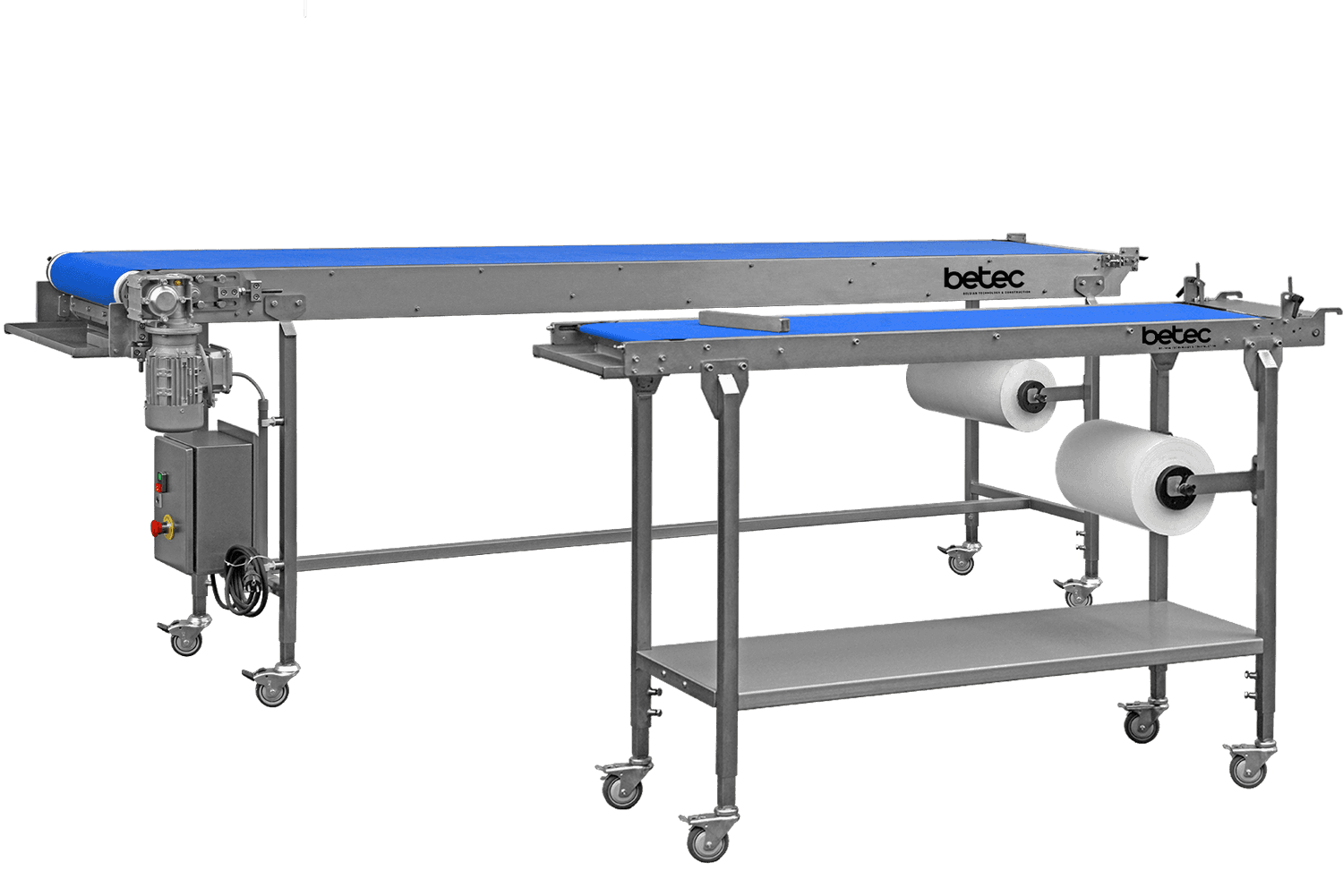

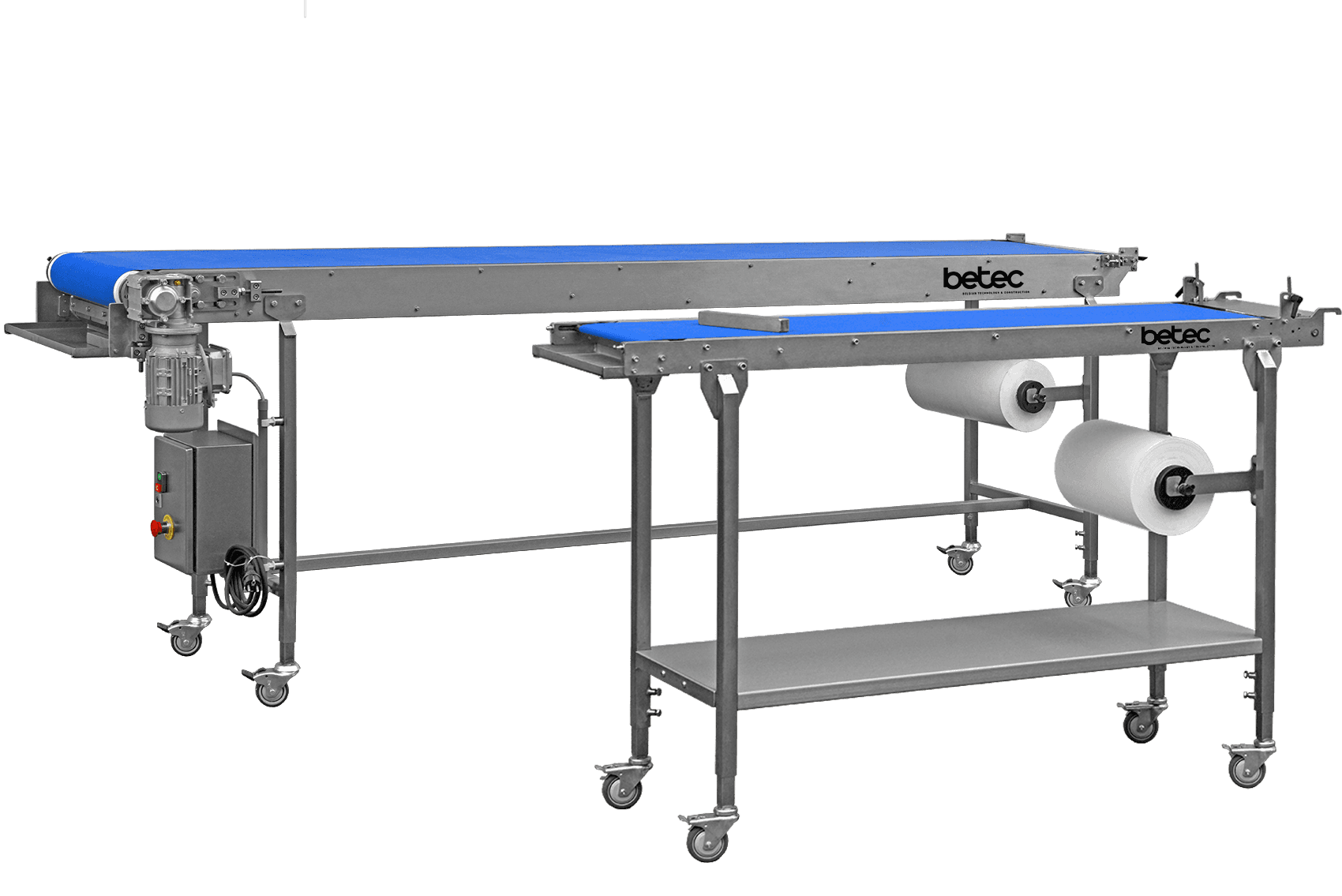

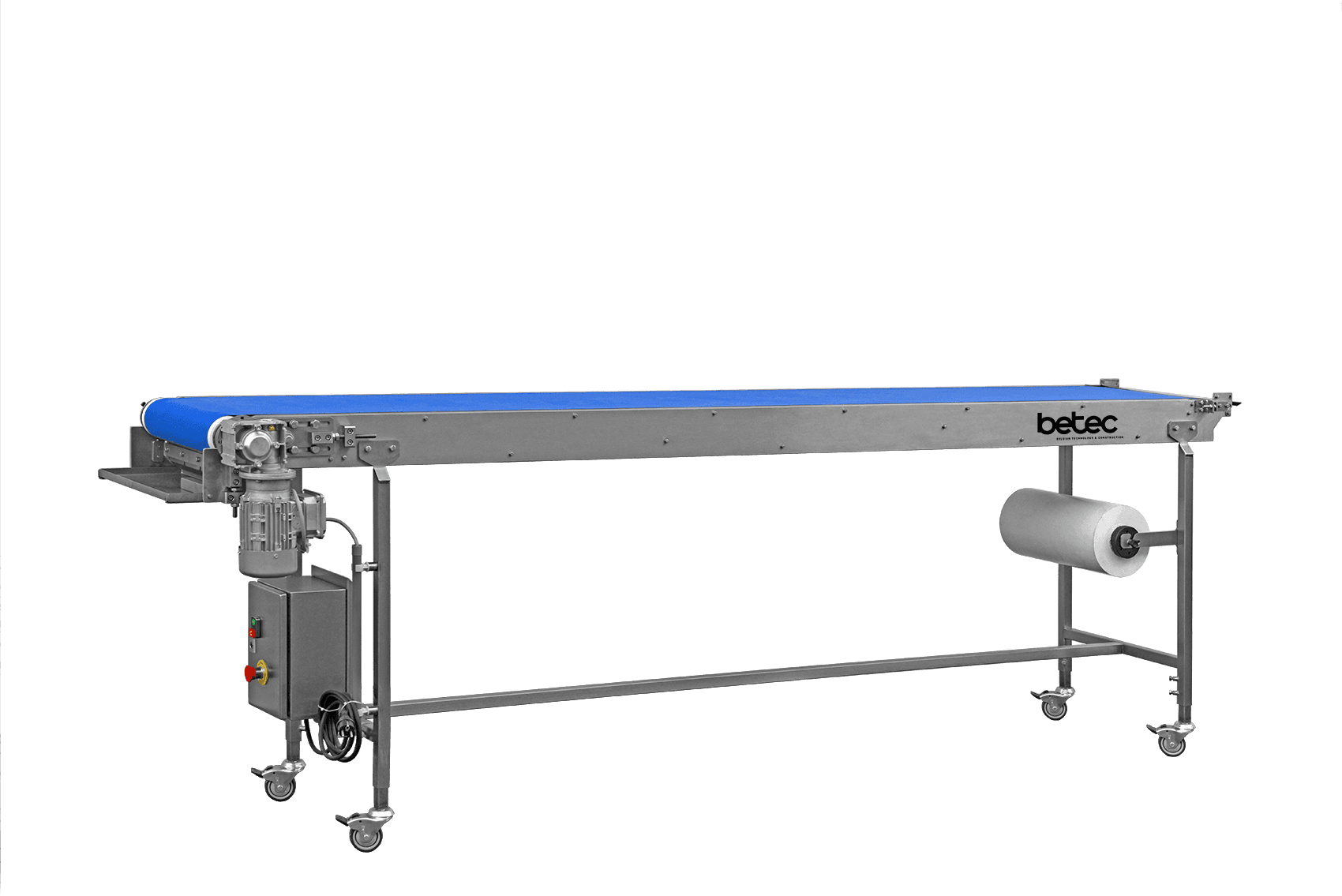

Product

TOC-...-1500

CONVOYEUR DE SORTIE AVEC ROULEAU DE PAPIER POUR MACHINE D'ENROBAGE

Entrez dans le monde de l'excellence chocolatière inégalée, où l'enrobage de vos produits chocolatés et confiseries devient une expérience fluide, sans avoir besoin d'un tunnel de refroidissement ! Découvrez notre convoyeur de sortie révolutionnaire avec un rouleau de papier, un outil essentiel pour les chocolatiers passionnés qui recherchent la perfection dans leur processus de production et qui souhaitent éviter la complexité d'un tunnel de refroidissement, même avec un espace ou un budget limité. Soyez émerveillé par le convoyeur de sortie idéal avec un rouleau de papier, vous permettant de déplacer sans effort des délices enrobés de la bande d'enrobage vers un chariot. Augmentez votre efficacité, améliorez votre flux de travail et laissez commencer la magie de l'enrobage de chocolat sans effort!

Caractéristiques et avantages :

Temps de séchage et durcissement complet :

Spécialement conçu pour traiter des produits enrobés de chocolat ou d'autres masses liquides, le convoyeur de sortie avec rouleau de papier offre une solution innovante. Ce convoyeur de sortie garantit que les produits nouvellement enrobés peuvent commencer à sécher et à durcir immédiatement avant d'être retirés du convoyeur de sortie. En utilisant une plaque en aluminium sous le papier, les produits enrobés peuvent être facilement déplacés du convoyeur de sortie vers le rack mobile. Sur ce rack, ils bénéficient du temps nécessaire pour durcir complètement. Une fois que les produits enrobés sont complètement durcis, ils peuvent être transférés au service d'emballage ou à l'étalage, puis trouver leur chemin jusqu'au client.

Évitez les interruptions ou les temps d'arrêt :

Évitez les temps d'arrêt de la bande d'enrobage ou de revêtement en transférant immédiatement les produits enrobés sur le rack de séchage dès qu'ils sont enrobés. Cela garantit un flux de travail continu, permettant de produire une quantité significative de manière efficace et artisanale. Évitez les temps d'arrêt constants de la machine d'enrobage. Transférez immédiatement les produits enrobés de la bande d'enrobage sans délai, maintenant ainsi la fluidité de votre flux de travail.

Alternative économique ou économiquement responsable :

Pour les chocolatiers plus petits ou en démarrage, la bande de convoyeur avec un rouleau de papier est une option économique comme alternative aux tunnels de refroidissement conventionnels.

Personnalisation et flexibilité :

Chez Betec, nous proposons des bandes de convoyeur de prise standard de 1,5 mètre, généralement alimentées par la grille d'enrobage. Cependant, nous pouvons personnaliser la longueur en fonction de vos besoins spécifiques. Optez pour un entraînement séparé pour une flexibilité encore plus grande.

Nez réglable pour une transition en douceur :

La bande de convoyeur de prise avec rouleau de papier est équipée d'un nez réglable, permettant une transition sans couture entre la bande d'enrobage et la bande de convoyeur de prise, aboutissant à une finition raffinée.

Rouleau de papier cristal pour une hygiène optimale :

Maintenez votre bande transporteuse propre grâce au rouleau de papier cristal intégré, prévenant la contamination et assurant un environnement de production hygiénique.

Avec le convoyeur de sortie incluant le rouleau de papier, vous optez pour une solution efficace et économique pour le séchage et le durcissement de vos friandises enrobées.

Contactez-nous aujourd'hui pour un convoyeur de sortie sur mesure qui répond parfaitement à vos besoins en matière de production de chocolat.

.png&w=1500&q=60)

.png&w=1920&q=60)

(4).png&w=1920&q=60)

.png&w=1920&q=60)